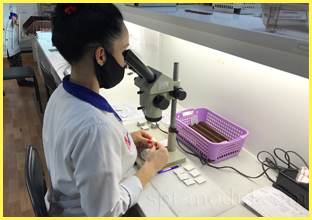

Our company maximize to the quality of producible products. Thermoelectric module is a complex device which is composed of many tiny parts and soldered connections. Quality control is implemented on all stages of products manufacturing (from growing of thermoelectric semiconductor material till packing of finished products).

Highly qualified inspectors check all parameters of the thermoelectric modules and devices by means of modern gages which include developed gaging equipment by S&PF MODUL specialists.

Monitoring of technological and production processes have been realized in accordance with procedure “Statistical process control” of IATF16949 at our company SPF Modul. Technological process is controlled by highly qualified production foremen and process engineers.

Periodic tests of finished products for reliability are carried out both in certified labs and in our own laboratory.

The level of product quality at the SPF Modul is constantly monitored using various statistical methods.

Employees, who are involved into the quality control of products, aimed at ensuring that the customers receives only defect-free products.